Automatic Injection Drug Dispensing System

Types of Automatic Injection Drug Dispensing System

It flexibly supports various injection drug dispensing needs and layout requirements.Its various unit configurations provide plenty of variations.

Lineup of Automatic Injection Drug Dispensing System

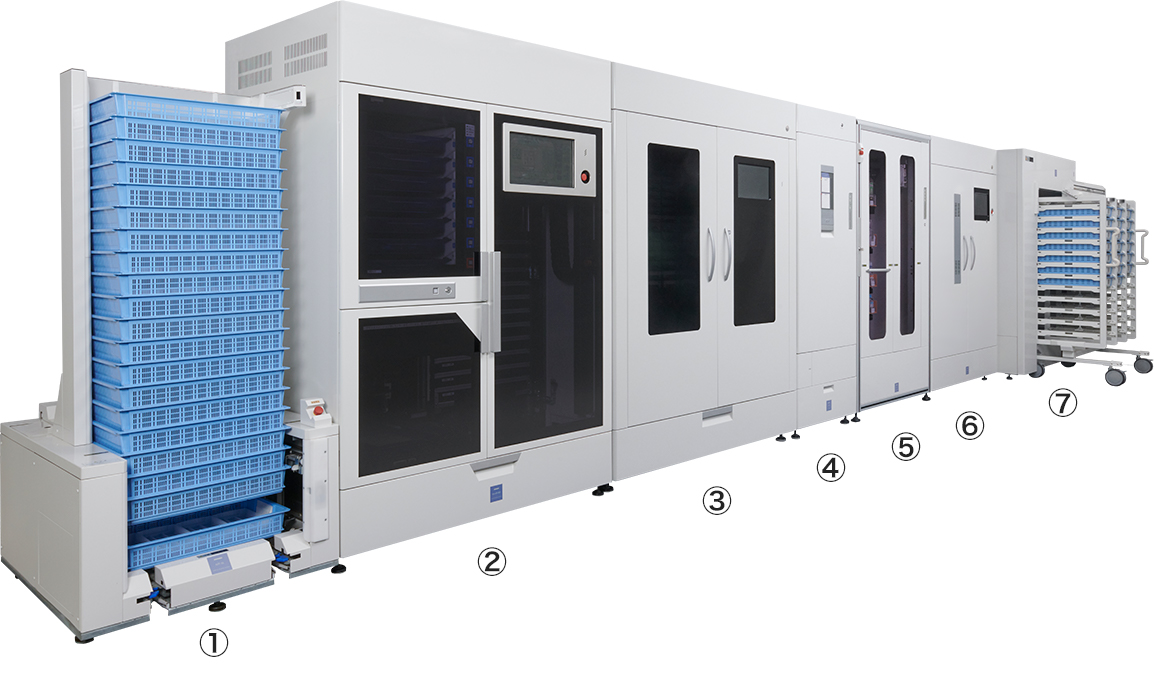

Configuration Example of Four-Part Dispensing

- Sorts and dispenses four equal parts to a single tray (supports more than 930 units per hour) *

- Even setting up the trays in the cart is fully automated, making it easy to transport it within the ward

- Innovative design that doesn’t need cassettes; makes it possible to dispense returned injection drugs

② Returned-Injection-Drug Dispensing Machine APF-RD

③ Injection Drug Dispensing Machine (Random Input Type) APRS-136/128

④ Special Drug Dispensing Machine APF-DB-P

⑤ Bottle Dispensing Machine BT-X

⑥ Label/Injection Prescription Printer Unit APRS-PR

⑦ Stack Lifter APF-PLB-P*When using the following setting: no reading out expiration dates; dispense 6 units on single tray.*The total processing speed varies depending on the line configuration and dispensing criteria.

-

Filling is simple and easy.

Dispensing is accurate yet speedy.

YS-APRS-136/128 Filling work becomes easy with random drug filling method, which means that you just simply need to randomly spread them on a filling tray.

The GS1 data bar and expiration date of each item are verified when being dispensed, ensuring accurate results.

With significant increase in the dispensing speed, a single unit can dispense more than 930 units per hour*.*When using the following setting: no reading out expiration dates; dispense 6 units on single tray.*The total processing speed varies depending on the line configuration and dispensing criteria.

Model YS-APRS-136/128 External Dimensions W1498×D850×H1880mm Processing Speed Dispensing Volume (Single Unit UT): >930 units/hour*When using the following setting: no reading out expiration dates; dispense 6 units on single tray.*The total processing speed varies depending on the line configuration and dispensing criteria. -

Supports automatic dispensing of

uniquely-shaped drugs via 5-consecutive polyampoules

Special Drug Dispensing Machine APF-DB-P/APB-28 "Medicine kits," "BOX-shaped drugs," "blister packs," etc., which cannot be loaded into the standard unit due to size and shape restrictions, can be automated using a special-medicine dedicated unit.Drugs that are linked together such as “twist-type ampoules” can be automatically separated when being dispensed using an optional ampoule cutter.

We provide solutions to strike an optimal balance between prescription frequency and load volume.Model APF-DB-P/APB-28 External Dimensions Main Unit: width 692 x depth 850 x height 1,880 mm/

Width 756 x depth 967 x height 1,880mmDispensing Speed APF-DB-P: about 1,000 units or 250 trays per hour (MAX)

APB-28: about 300 units/hour (MAX) -

A new system that can flexibly handle

a variety of drug shape

Bottle Dispensing Machine BT-X Also supports drugs with shapes that make it difficult for independent storage and lifting it by its bottleneck. The newly developed straight-bar holding system allows picking up drugs with various shapes.

Easily verify the remaining volume because it's transparent. Its smart body design makes installation a snap.Model BT-X External Dimensions Main Unit: width 1,098 x depth 850 x height 1,880mm Dispensing Speed About 300 units/hour (MAX) -

Dedicated dispenser that supports

automatic dispensing of drugs in soft bags

Soft Bag Dispensing Machine APF-SB Fully-automatic dispensing of soft bag medicine onto taper trays via robot arm neck-catch system.

The main unit has 15 compartments, which can each store 10 units of both 250 ml and 500 ml soft bag medications each. Optimize efficiency via the family-set dispensing function that can dispense the same drug from different compartments, which reduces the amount of filling required, even for high-volume drugs.Model APF-SB External Dimensions Main Unit: width 1,360 x depth 1,000 x height 1,880mm Dispensing Speed 400 units/hour (MAX, single operation) -

No need to sort out

returned injection drugs.

Supports automatic management of expiration dates and dispensing

Returned-Injection-Drug Dispensing Machine APF-RD The workload of verifying the expiration of returned injection drugs, sorting and re-shelving them places a lot of burden on pharmacists.

We developed a dispenser that can no only reduce human error, but also automatically dispense drugs after receiving each prescription data, while managing the expiration dates.Model APF-RD External Dimensions Main Unit: width 1,298 x depth 850 x height 1,880mm Dispensing Speed About 14.4 seconds/2 units (dispensing) -

Automatically packages drugs in a bag, and sets them on a tray, and into a cart.Provides a wide range of automatic dispensing methods

Bagging Unit + Bucket Lifter

FT300-BA bag-filling system in which the medicine bag is placed in an outer bag that’s transparent on one side, and the description of the injection prescription is printed on the bag.The medications are dispensed in a way that simplifies the inspection, similar to the tray dispensing method.

Bags are uniquely filled for each patient (daily dosage or 1 application unit), and can be dispensed into each ward bucket.Model FT-300-B/FT-300BT External Dimensions Main Unit: width 2,170 x depth 850 x height 1,880 mm/

Width 1,430 x depth 850 x height 1,880mmOn-board Printer Thermal Transfer Printer x 2 -

Compact design due to

integrated label /

injection prescription printing.

YS-APRS-PR By integrating the label and injection prescription printer unit, the width became 22.5 cm smaller than the conventional model.(Compared to our company’s products)

The robot arm properly aligns the labels and injection prescription before dispensing them, allowing you to immediately read the printed details during inspection, which eliminates the need to manually hold each item in hand for inspection.

It’s also equipped with two label printers and two injection prescription printers. Therefore, interruption never occurs, even if an error or defect occurs in one of the printers because the counterpart printer will continue the task.Model YS-APRS-PR External Dimensions W1,315×D850×H1,880mm On-board Printer Color Laser Printer x 2

Monochrome Label Printer x 2

Stock-Out Information Printer x 1 -

It’s a special printer

dedicated to dispensers,

and can produce a complete output

on a single line

Label Printer Unit APF-PRL/Color Injection

Prescription Unit Printer Unit APF-PRCA bag-filling system in which the medicine bag is placed in an outer bag that’s transparent on one side, and the description of the injection prescription is printed on the bag.The medications are dispensed in a way that simplifies the inspection, similar to the tray dispensing method.

Bags are uniquely filled for each patient (daily dosage or 1 application unit), and can be dispensed into each ward bucket.Model APF-PRL/APF-PRC External Dimensions Main Unit: width 650 x depth 850 x height 1,880 mm/

Width 890 x depth 850 x height 1,880mmOn-board Printer Label Printer x 2 / Color Laser Printer x 2 / Stock-Out Information Printer x 1 -

A magical experience created with a little ingenuity. Anyone regardless of gender can easily set various trays

Supply Lifter APF-SL-P The challenge for hospital pharmacies is their work space design. They have large equipment needed to handle vast volumes of prescriptions, while simultaneously securing workspace, effectively store, transport, and set empty trays.With 4-part taper trays, you can store 40 empty trays at a time, and can automatically set the next 40 trays that you had preloaded in advance.

Model APF-SL-P External Dimensions Main Unit: width 750 x depth 800 x height 1,594mm Tray Storage Capacity 40 trays (4-part taper trays; MAX)

80 trays (4-part taper trays; when a dedicated wagon is used; MAX) -

Can stack up to 15 dispensing trays.

Can link up to 10 units

Stack Lifter APF-PL-P/APF-PLB-P A 4-part tray stacking unit.We offer two types: APF-PL-P (horizontal tray stacking system) and APF-PLB-P (vertically stack up patient card sets by facing it front).

After dispensing the main output via the dispensing lifter, this unit can also separately dispense trays for emergencies and extraordinary circumstances while it is printing regular prescriptions.

Facilities that don’t have as much injection prescriptions can simply use this unit alone to produce outputs.Model APF-PL-P/-PLB-P External Dimensions Main Unit: width 690 x depth 514 x height 1,880 mm/

Width 480 x depth 725 x height 1,880mmTray Storage Capacity 15 trays (MAX) -

With patient card rewrite mechanism.

Can also automatically set trays into a dedicated rotation cart

Dispensing Lifter with Rewrite Card

APF-RTCD-PEquipped with a rewrite mechanism that can write out new patient information by removing the rewritable and reusable patient card that has been set in the 4-part tray, and deleting the existing information.It’s fully automated including setting the trays.

A model without the card rewrite mechanism (YS-APF-RT-P) is also part of the lineup.Model APF-RTCD-P External Dimensions Main Unit: width 1,450 x depth 1,048 x height 1,880mm Tray Storage Capacity 36 trays in the rotation cart (MAX) -

Automatic cart loading system +

card rewrite system

Dispensing Lifter AP-RT-100 Similar to the tray dispensing system, this mechanism can automatically delete all patient information on the rewrite card that has been set in the tray while the injection prescriptions, labels and drugs are being dispensed, and then write new information onto the card and reload it onto the tray.After the writing has been completed, the trays are automatically set into the Yuyama rotation cart.

It can dispense based on each ward and ward floor, and can be smoothly transported.Model AP-RT-100 External Dimensions Main Unit: width 1,220 x depth 875 x height 1,880mm Tray Storage Capacity 27 trays in the rotation cart (MAX) -

Smoothly provide medication to your wards

Personal Delivery Magic

Rotation Cart

(For 4-part trays, taper trays, straight trays)Yuyama’s proprietary devices are perfect for your operation, management, storage and privacy protection. Experience Personal Delivery Magic, which smoothly provides injection drug dispensation trays to your wards.

By simply twisting the side lever, lock all storage trays with a single touch. The top dedicated cover can prevent access to the injection drugs on all trays.External Dimensions Width 1,060 × depth 718 × height 1,558 mm Weight 45kg approx. Material Steel Color White Tray Up to 36 pcs (4-divided-tray) Function One touch lock lever, Tray cover on the top part, Jointable up to 3 units. -

A polished design based on the feedback from onsite medical professionals

A new style + flexibility

Residential Injectable Delivery Risk Management System SecuillーStand Injectables in wards, ICUs and emergency rooms pose various onsite dangers within a hospital, such as arrangement mistakes due to relying only on verbal communication, near-miss incidents, missed claims due to unauthorized use or theft, etc.

Secuill-Stand was developed based on the feedback of many medical settings as an injectable risk management system and provide flexible solution to the operation that differs in each department.

One of the characteristics of Secuill-Stand is the ability to combine up to four additional units with a single control unit.

Cassette units and refrigeration units can be arranged within the main unit at the site according to the particular requirement.Model YS-SE-STD-CTRL External Dimensions Main Unit: width 560 x depth 560 x height 1,733mm

(Refrigerator Specification)Maximum Number of Loadable Drug Types Max: 34 drug types