- TOP

- Sustainability

Sustainability

YUYAMA SDGs Initiatives

Going beyond previous efforts and pursuing new activities to achieve our goals.

The Sustainable Development Goals (SDGs) adopted by the United Nations General Assembly in 2015 marked a dramatic shift in thinking towards environment protection and economic growth, calling for companies to actively promote initiatives that contribute to the development and improvement of a sustainable society.

The SDGs are a major goal for our company, and we are pursuing business activities with a focus on achieving a sustainable society and the SDGs.

As a responsible manufacturer committed to the SDGs and pioneering the future of dispensing, we aim to drive changes in the local environment and become a reliable partner to healthcare professionals in the pharmaceutical field.

-

- Automated External Defibrillator (AED) In-house Training

- Carrying Out a Blood Donation

- Reducing Out-of-hours Work and Promoting a Healthy Work-life Balance

- Provide Products and Services that Address Social Issues

Automated External Defibrillator (AED) In-house Training

Yuyama Manufacturing and Yuyama hold regular in-house AED training sessions with support from Toyonaka city emergency paramedics. Each session (approx. three hours) attracts about 10 to 15 employee participants, with numbers increasing each year along with growing in-house awareness and interest.

Scenes from the Training Session

Explanations from the Toyonaka City paramedics.

Participants listening intently to the lecture.

CPR hands-on practice while listening to lectures. Award from Toyonaka City

Summary

“You never know when or if you will come across someone suffering from cardiac arrest or sudden collapse. It is said that the chances of survival decrease by 10 percent for every minute after the onset of ventricular fibrillation.

It takes about six minutes for paramedics to arrive on the scene, so waiting for an ambulance significantly reduces the chances of saving a life. However, having an AED close by can greatly increase the chances of survival.

In such emergencies, the difference between being able to use an AED or not is decisive and, thus, we are to continuing to train personnel who can quickly respond to emergencies on the spot.”

Blood Donation Initiatives: Report

We hold regular blood donation drives for employees at our head offices, production factories, and R&D buildings. Blood is vital for saving the precious lives of people who are in need of a blood transfusion due to illness or serious injury. We share the values and philosophy of the Japanese Red Cross Society and are committed to working with them to help save lives.

Dedicated area

Dedicated area set-up in the parking lot

Japanese Red Cross Society blood donation bus

Employee donating blood May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Donors 134 pers. Stopped due to

COVID-1988 pers. 97 pers.

Reducing Out-of-hours Work and Promoting a Healthy Work-life Balance

- Leveraging IT in work operations to reduce working outside of regular working hours.

- Promoting more diverse work styles such as going directly home (without stopping by the office), work-from-home (WFH), and shorter work days.

- Encouraging employees to use paid leave and childcare leave

Full-time employee data

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Overtime hours per employee per month 26.4hrs. 29.1hrs. 29.4hrs. 28.8hrs. Number of paid leave days taken per employee 8.3days. 9.2days. 9.2days. 9.8days. Full-time and part-time data

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Number of WFH employees 227pers. 295pers. 223pers. 137pers. Short work day employees 5pers. 10pers. 15pers. 17pers. Number of employees taking childcare leave 13pers. 9pers. 12pers. 15pers. Number of employees taking nursing care leave 0pers. 1pers. 0pers. 1pers.

Provide Products and Services that Address Social Issues

Robotize Dispensing Operations and Drive Change

Recent demands for pharmacists to move from product distribution to direct patient care, as exemplified by community pharmacists, have increased the need for automated dispensing operations. The introduction of our robotic dispensing systems, including DimeRo II, MiniDimeRo, and ChemoRo the Spike, helps pharmacists dedicate more time to caring for patients.

Efforts to Improve Medication Complianc

To ensure that patients take their medications correctly, we have developed a range of printing techniques for medication packaging, including color printing capabilities, automatic four-color pen liners, and full-surface color printing.

Nationwide After-sales Locations

With over 50 after-sales and maintenance locations across Japan, we can respond swiftly to requests for repairs and offer customers a sense of security and safety.

-

- Showrooms, Factory Tours, and Training Support for Pharmacists and Pharmaceutical Students

- Support Kids Pharmacy

- Proactive Employee Training

- Showcase: “Treasure Chest for the Future” (Mirai-no-Takarabako) 2023, in Osaka

- Participation in the Future Class

Company Visits by Education Institutions: Toyonaka City Pharmaceutical Association

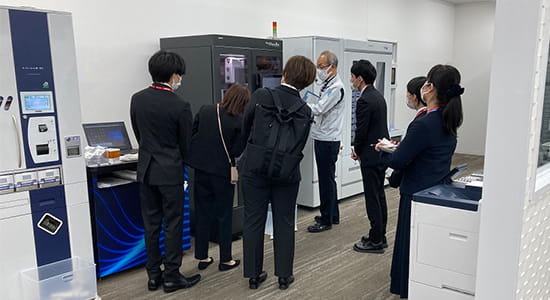

The Toyonaka City Pharmaceutical Association organizes a series of annual seminar events for pharmacy students in the local prefecture as part of its efforts to foster “future pharmacists.” One of the events offers students the opportunity to visit our company for a first-hand and in-depth look at our dispensing equipment. In addition to the latest equipment, students also learn about the manufacturing processes, quality controls, and the various steps taken before the products are shipped out to the customer. We were impressed with the intent and seriousness in the eyes of the students listening to the seminars.

Scenes from the Seminar in Our Conference Room

Numerous students and interns attended the seminar.

Participants discussing the present and future state of pharmacists. Scenes from the Showroom and Factory Tour

Numerous students and interns attended the seminar.

Support Kids Pharmacy

Yuyama supports “Kids Pharmacy” for children of elementary school age and younger. We hope to provide an opportunity for children to experience the profession of a “pharmacist” while having fun, and for parents to learn what kind of work a “pharmacist” does until they receive their medicine at the actual pharmacy.

Trying out the perfect-fitting lab coat.

Picking medications (sweets and candy) from the pill rack.

Operating the medicine packaging machine and experiencing single-packet packaging.

At the end, the children put medication (sweets and candy) in a medication pouch and took a commemorative photo in their white lab coats! 2018 “Children’s Kasumigaseki Tour Day” (Tokyo)

““Children’s Kasumigaseki Tour Day” is an initiative by the Ministry of Education, Culture, Sports, Science and Technology (MEXT) in cooperation with government ministries and agencies in the Kasumigaseki district that aims to deepen parent-child interactions and offer children a broad overview of society through talks, experiences, and interactive tours of ministry offices and industries over the summer vacation.

We participated by exhibiting products and involving participants in work experience activities (Held from August 1 to August 2, 2018).”

2019 “Children’s Kasumigaseki Tour Day” (Tokyo)

“Children’s Kasumigaseki Tour Day” is a collaborative initiative of the Ministry of Education, Culture, Sports, Science and Technology (MEXT) and other local ministries and agencies. It features talks, interactive tours of ministry offices and industries, over the summer vacation, and aims to deepen parent-child interactions and offer children the opportunity to learn about society at large through hands-on experiences.

In continuation from the previous year, we exhibited our products and offered interactive experiences of work tasks to participants in the program (Held from August 7 to August 8, 2019).

■ Exhibited Product

Reno-s! Ultra Compact Packaging Machine**The displayed Reno-s was customized with a clear top cover and hopper so that viewers could see the medication route.

Proactive Employee Training

- Creating and implementing skills maps and education schemes.

- Encouraging participation in external outside seminars, correspondence courses, online learning, and exhibitions and book purchases.

- Conducting in-house training and study sessions.

- Distributing e-mails that help employees keep up to date with current industry news, legal affairs, and other related topics.

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Number of External Training Sessions & Lectures 1,135 1,444 1,644 2,763

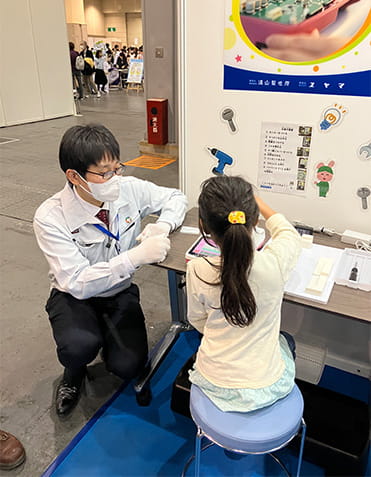

Showcase: “Treasure Chest for the Future” (Mirai-no-Takarabako) 2023, in Osaka

“In 2023, we showcased the “Treasure Chest for the Future” (Mirai-no-Takarabako) in our office. The “”Treasure Chest for the Future” is part of a community-based interactive event that aims to enrich local communities by nurturing children’s hopes and dreams.During the event, participants could try their hand at assembling the OnedyEX2 Electronic Balance-Integrated Inspection System and witness our miniDimeRo Powder Drug Dispensing Robot on display. Over the two days, 130 parents and children experienced assembling the OnedyEX2, hands-on.”

(Held from November 11 to November 12, 2023)

URL‥‥https://mirainotakarabako.com/osaka/

Participation in the Future Class

“We participated in the “”Classes of the Future”” event hosted by BatonLink Co., Ltd. at Kitasenri High School in Osaka Prefecture from September 6th to November 29th, 2023.

On October 18, two of our employees gave a lecture at Kitasenri High School on the current state of healthcare treatment in Japan and our business initiatives to solve the issues”Corporate Introduction & Pre-interview Movie

“Scenes from the Lecture:

Mamika Itabashi and Shota Uchiyama Human Resource Development Section General Affairs Department”

BatonLink Co., Ltd. Press Release

https://prtimes.jp/main/html/rd/p/000000005.000125542.html

-

Establishment of an On-site Childcare Facility (Osaka Head Office)

We established an on-site childcare facility on the second floor of our Osaka head office to help create a valued work environment that allows employees to balance work life and childcare with vitality. The facility has a small maximum capacity of 10 children to ensure each child’s individuality is valued, and provides homemade lunches and snacks.

-

A 100% Natural Energy-powered Factory (Okayama Factory)

Solar panels put into operation at our Okayama Factory in April 2023 have reduced carbon dioxide emissions by 34% for the entire company and by 50% at our Okayama Factory. Our Okayama Factory also receives CO2-free electricity from Chugoku Electric Power Company for the remaining 50%, making it a 100% natural energy-powered factory.

-

- Promote Proposals for Improvements

- Implement Employee Satisfaction Surveys and Promote Work Style Reforms

Promote Proposals for Improvements

- Introduced an improvements committee in each department as part of a system for gathering proposals for improvements from all company employees.

- Each month, our improvements committees in each department gather exemplary improvements and disseminates them to the entire company.

- Every six months, we select an awardee for The Best Proposal Award and The Most Proposals Award.

- Each year, we select the most outstanding improvement for the Outstanding Employee Award.

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Number of Improvements 4,150 4,391 3,923 5,556

Implement Employee Satisfaction Surveys and Promote Work Style Reforms

In 2018 we executed a company-wide employee satisfaction survey and rolled out the Yuyama Employee Satisfaction Improvement Declaration the following year in 2019.

(1) Develop an education system and training environment to enable and strengthen systematic human resource development.

(2) Develop necessary systems and re-engineer our operations to improve business productivity.

(3) Strengthen internal communications and review the evaluation system to ensure motivating goals and fair evaluation.The above (1) and (2) are being planned and implemented in each department.

The above (3) was started in 2020 with a new employee wage system.We intend to continue conducting employee satisfaction surveys as part of a continual effort to foster a motivating and rewarding workplace for our employees.

-

- Unique Product Development to Create Next Generational Standards

- Invention Promotion and Utilization

- Development and Production of Industrial Robots (In-house development of robotic equipment)

Unique Product Development to Create Next Generational Standards

September 1,

September 1,

2022Received the “24th Automatic Identification Systems Grand Prize” for 2022FY

Our TABSORT+ Single-Packed-Tablet Sorting Machine was selected for the “24th Automatic Identification Systems Grand Prize” (2022FY) sponsored by the Japan Automatic Identification Systems Association.

The Automatic Identification Systems Grand Prize is awarded in commendation of cutting-edge and advantageous automatic identification and recognition technologies and systems to promote the development, dissemination, and awareness of such technologies and systems.

November 1,

November 1,

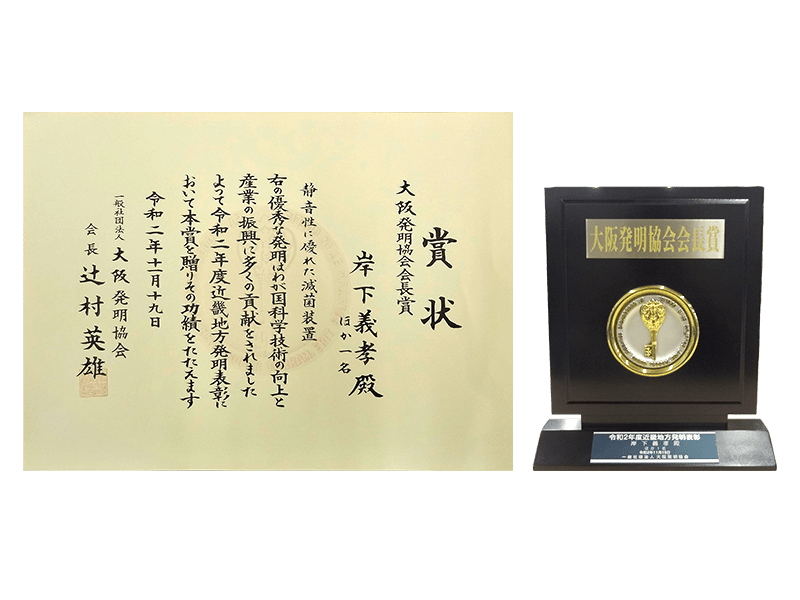

2020Received the “Osaka Institute of Invention and Innovation Chairman’s Award” at the 2020 Kinki Regional Inventions Awards

Our Fully-Automatic High-Pressure Steam Sterilizer YS-A-C108 was nominated as the winner of the “Osaka Institute of Invention and Innovation Chairman‘s Award” at the 2020 Kinki Regional Inventions Awards.

September 1,

September 1,

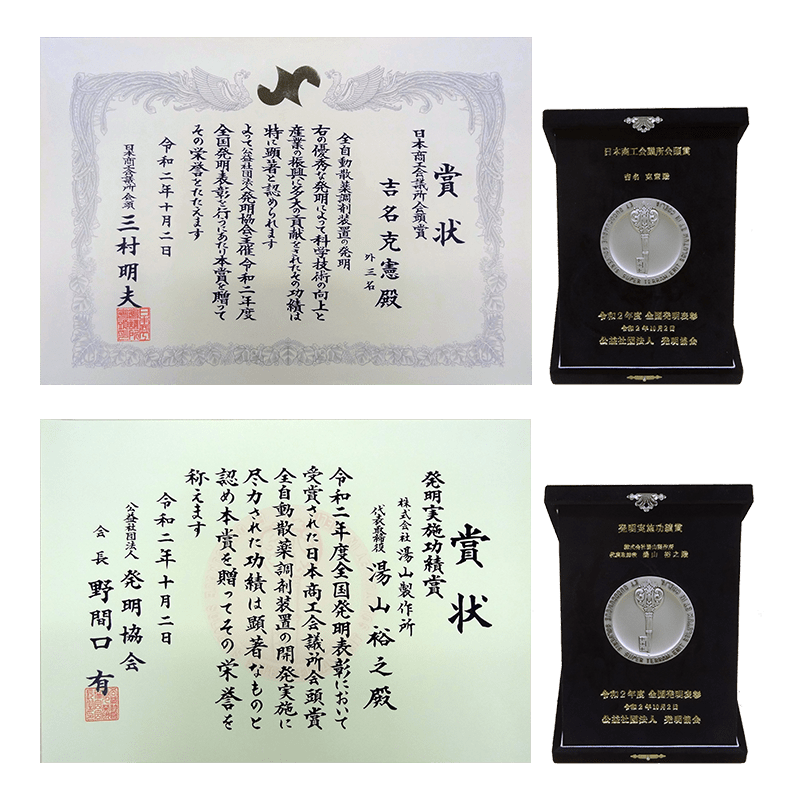

2020Awarded the “The Japan Chamber of Commerce and Industry Chairman’s Award” and “Invention Implementation Award” at the 2020 National Inventions Award, Japan.

Our DimeRo Powder Drug Dispensing Robot was selected for the “The Japan Chamber of Commerce and Industry Chairman’s Award” and “Invention Implementation Award” at the 2020 National Inventions Awards, Japan.

January 1,

January 1,

2020Awarded the “2019 Osaka Excellent Invention Grand Prize”

Our DimeRo Powder Drug Dispensing Robot was selected for the “2019 Osaka Excellent Invention Award Grand Prize” sponsored by the Osaka Institute of Invention and Innovation.

Invention Promotion and Utilization

As an industry leader in creating foundations for technological innovation, we are committed to firmly protecting and leveraging achievements in research and development and intellectual property.

We believe that innovation is an essential tool for the continuous development and production of industry-leading products and have implemented an “Employee Invention System” as part of our framework for generating high-quality ideas.Each month, our development-related divisions and Intellectual Property Departments gather to evaluate and review idea proposals and consider which proposals to progress forward to the patent application and know-how management phases.

We also provide guidance on matters for current and future technological innovations which are needed for subsequent idea proposals.

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Number of Idea Proposals 853 678 521 713

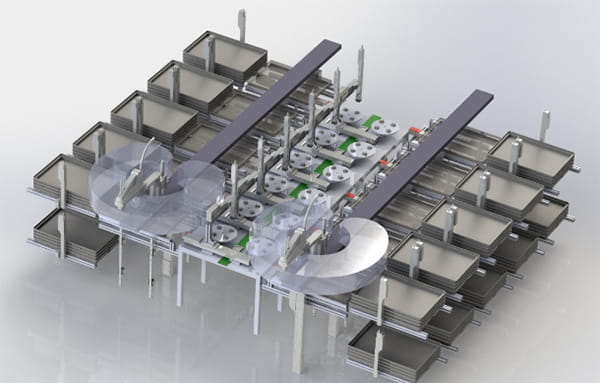

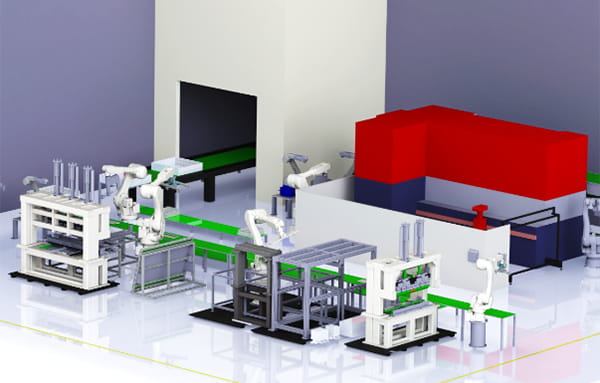

Development and Production of Industrial Robots (In-house development of robotic equipment)

At our main factory, we have developed our own industrial robots to automate the assembly of our in-house produced products.

- Automatic frame welding

- Tablet cassette assembly

- Small parts assembly

- Balance assembly

- Dispensing table processing and assembly

-

- Promote Employment of Persons with Disabilities

- Company Tours for Persons with Disabilities (Osaka Head Office)

Promote Employment of Persons with Disabilities

- With the relocation of our Osaka head office to a new building, we implemented numerous structural improvements to create a safe and amicable working environment for persons with disabilities. These improvements include a barrier-free floor, one wheelchair-access elevator, an ostomate-friendly multipurpose restroom, and a break room that serves as a relaxation area.

- On the human services front, we introduced key personnel to welcome and look after employees in each department and a consultation system so that they can discuss matters at any time.

- In fiscal 2020, we received the 2020 Award for Excellence in Employment of Persons with Disabilities from the Osaka Employment Development Association Inc.

June 2020 to

May 2021June 2021 to

May 2022June 2022 to

May 2023June 2023 to

May 2024Disabled Persons Employment (%) 2.30% 2.73% 2.00% 2.06% * Figures shown in the Report on Employment Status of Persons with Disabilities

Company Tours for Persons with Disabilities (Osaka Head Office)

- Our Osaka head office conducts company tours for persons with disabilities in cooperation with Hello Work (Employment Service Center), free job placement agencies in Toyonaka City, and labor support offices.

- The tours aim to provide many people with disabilities with opportunities to learn about the manufacturing industry and to support their employment.

- We believe that it offers a good chance to get to know our business and our work environment, hopefully leading to employment.

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Number of Tours Conducted 7 8 11 14

-

- Support Dispensing Recovery Activities in the Event of a Disaster

- In-house Disaster Countermeasures

- Participation in Community-based Benefit Activities (Open Hospital)

- Establishment of East Japan Logistics and Distribution Center

“Osaka Pharmaceutical Association Inc. and YUYAMA Co., Ltd.

Notice of Conclusion of the Agreement on Cooperation in Disaster Relief Activities”On August 6, 2018, YUYAMA Co., Ltd. and Osaka Pharmaceutical Association Inc. signed an agreement concerning the use of “Disaster Dispensing Support Vehicles.”

In the event of a disaster, we will lend our trucks, which are normally loaded with our products and used for technical training of our employees across Japan, to the Osaka Pharmaceutical Association. The Osaka Pharmaceutical Association will then use the trucks, free of charge, to deliver pharmaceutical supplies to disaster-affected areas, unload the supplies from the truck at the destination, and provide dispensing services near relief stations set up at evacuation centers and other locations.Scenes from the Day

As a general rule, the trucks will be delivered to the Osaka Pharmaceutical Association, as “Disaster Dispensing Support Trucks” for dispatch to disaster-affected areas and will be loaded with a compact packaging machine and dispensing bench only. Once received, the Osaka Pharmaceutical Association will load the truck with medications or lightweight pill racks and will be responsible for driving the trucks to disaster-affected areas. If the trucks are being used for training near the disaster, at the time of occurrence, both parties will consult and determine the best plan of action based on the circumstances.

Participating in Disaster Drills

(Osaka General Medical Center, Osaka Prefectural Hospital Organization

Acute & Comprehensive Medical Center IAA)On September 11, 2018, we set up a “Disaster Dispensing Support Vehicle” with the Osaka Pharmaceutical Association as part of our involvement in a disaster training exercise held at the Osaka Prefectural Hospital Organization Acute & Comprehensive Medical Center.

On the day of the training, numerous physicians participated in the exercises, which were designed to simulate a real disaster, including transporting people in need of rescue.

Scenes from the Day

In-house Disaster Countermeasures

- Development of a disaster response manual and system for immediate response.

…Confirm safety.

…Establish a disaster response headquarters.

…Assess affected areas.

…Confirm the status of employees and their families.

…Provide necessary supplies and physical goods.

…Assess traffic and transportation conditions.

…Provide support to customers and clients, and cooperate with the pharmacists’ association.- We have implemented a list to centrally manage the location and placement of basic supplies such as water, and other equipment such as high-pressure cleaners and compressors.

- For basic necessities, we installed disaster-type vending machines (vending machines that allow anyone to easily retrieve beverages free of charge in the event of a disaster or emergency) in our Osaka Head Office.

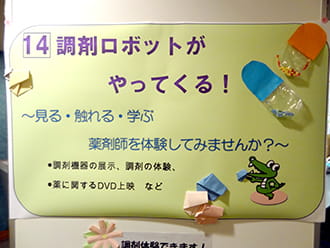

2018 Toyonaka Municipal Hospital Open Hospital

We were pleased to participate in the Toyonaka Municipal Hospital Open Hospital 2018, following on from the last year.

The event was designed to allow local citizens to see the normally behind-the-scenes hospital facilities, medical staff, and operations in an effort to broaden community knowledge of Toyonaka City Hospital as a trusted center for protecting the health of local citizens.

The event featured a variety of hands-on events and exhibits, introducing the hospital’s operations, facilities, and medical staff, which normally cannot be witnessed daily.

Held on: November 10, 2018

URL・・・https://www.city.toyonaka.osaka.jp/hp/shokai/koho/magazine/magazine.files/news49_1.pdfScenes from the Day

2017 Toyonaka Municipal Hospital Open Hospital

We were pleased to participate in the 2017 Toyonaka Municipal Hospital Open Hospital.

This event was organized by the Toyonaka Municipal Hospital to introduce not only the facilities, medical staff, and operations of the hospital, which are rarely seen in daily life, but also to invite participants to hands-on experiences in dispensing of medicine and cardiac catheterization, alongside hospital concerts and so on.Held on: November 11, 2017

URL・・・https://www.city.toyonaka.osaka.jp/hp/shokai/koho/magazine/magazine.files/news45_1.pdfScenes from the Day

Establishment of East Japan Logistics and Distribution Center

We established and started operation of the “East Japan Logistics and Distribution Center” on April 1, 2023, as follows.

Facility name:MFLP Prologis Park Kawagoe

Location: 1-9-3-401, Minamidai, Kawagoe City, Saitama, Japan

Operating Company: Tsubame Express Co. Ltd. (Saitama FC)

This center will stock a certain amount of consumables such as medication packaging papers produced at our Okayama Plant to ensure a smooth supply of consumables in the eastern Japan region and a stable supply in the event of a disaster.

The logistics and distribution center, MFLP Prologis Park Kawagoe, offers excellent access to the Kanetsu Expressway, Ken-O Expressway, Tomei Expressway, Chuo Expressway, and the Tohoku Expressway. In terms of our business continuity plan (BCP), the center is located in an area with a low risk of earthquake and flood damage. It is built to be earthquake- and fire-resistant, has a disaster prevention center staffed 24 hours a day, 365 days a year, an emergency power supply, and a satellite phone.

MFLP Prologis Park Kawagoe (center is located in the 401 area on the 4th floor)

-

- Pursue In-house Product Initiatives

- Recycling and Reuse of Work Clothes

- Recycling cardboard and paper waste.

Pursue In-house Product Initiatives

- Labeling materials for plastic (molded) parts for appropriate disposal in the recycling process.

- Verifying actual equipment and products throughout the development process to make improvements, such as reducing the number of parts and screws, that facilitate more effective recycling.

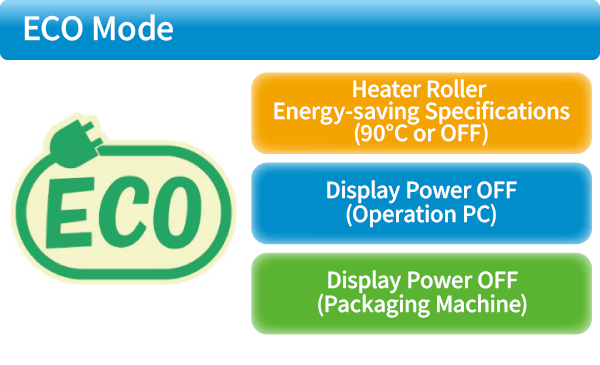

- Incorporating power-saving modes (eco mode) in our products.

- Providing updated online data to reduce CD-ROM usage.

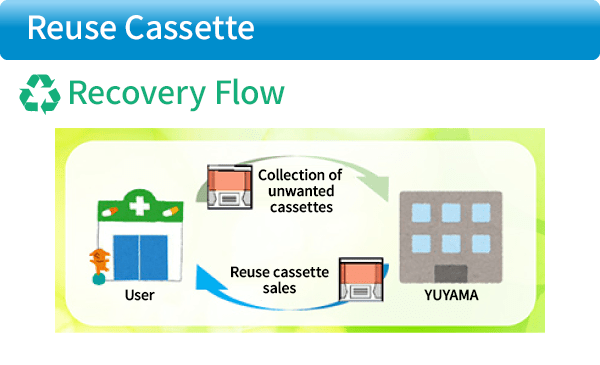

- Collecting used cassettes from users and using them to manufacture new cassettes (tablets and PTP).

- Reusing left-over medication packaging paper (unprocessed/uncut paper rolls) from the manufacturing process as protective sheets.

Recycling and Reuse of Work Clothes

- Collecting old workwear and recycle them into polyester or thermal energy.

- Donating to foreign nations.

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Volume of Recycled/Reused Workwear 937.3kg 452kg 48.65kg 58.95kg Donating Workwear to Myanmar

Since 2016, we have been cleaning used workwear worn by our employees and donating them to developing countries (Myanmar) and other countries through the nonprofit organization Bridge Asia Japan.

We collect the used workwear, mostly from seasonal changeovers of workwear (biannual), and donate about 50 complete top/bottom sets, a total of 100 pieces, twice a year. The donated workwear is used in vocational and technical training schools.

People in Myanmar wearing donated work clothes.

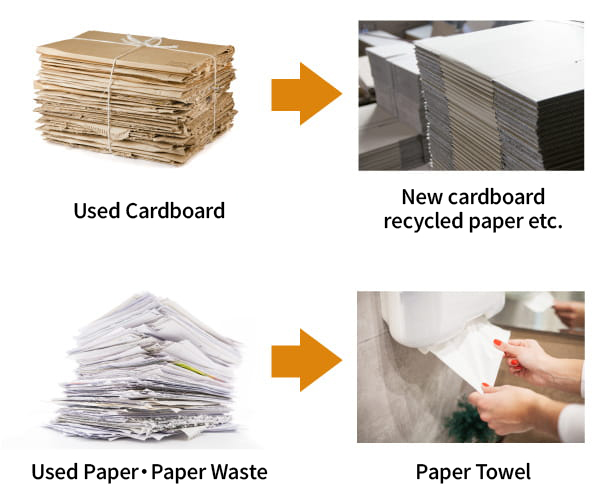

Recycling cardboard and paper waste.

- Reusing cardboard boxes as recycled paper.

- Recycling paper waste as paper towels.

- We purchase recycled paper towels.

-

- Pursue Eco-cap (PET Bottle Cap) Initiatives

- Use Low-pollution Vehicles

- Reduce Green House Gas Emissions

Pursue Eco-cap (PET Bottle Cap) Initiatives

All our employees at Yuyama Manufacturing/Yuyama are committed to PET bottle cap recycling as part of our CSR and environmental activities.

We collect bottle caps from used PET bottles and sell them to recycling companies through the Ecocap Promotion Association to be recycled as resources. Benefits are used to fund initiatives that contribute to society including vaccine support for children around the world, donations for earthquake disaster relief, environmental education at schools, and job creation and independence schemes for people with disabilities, alongside contributing to the reduction of CO2 emissions. This initiative offers us exceptional reach and opportunity to support the environment while contributing to a diverse range of people and circumstances.

YUYAMA Initiatives

Summary

“As of March 2024, we have provided a cumulative total of 960,151 PET bottle caps to the Ecocap Promotion Association. When calculated simply in terms of the amount of CO2 generated during disposal, this equates to approximately 7,033 kg of CO2 (430 caps weighing 1kg generates 3,150g of CO2).

Small things add up and we are excited to how such a small act can make such a big difference. We will continue with these activities.”

Use Low-pollution Vehicles

- We are gradually switching our company vehicles over to hybrid vehicles (VH).

- From Autumn 2022, we began introducing the electric vehicles.

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Number of Company Vehicles 536 540 548 560 Number of HVs 96 157 206 239 Ratio of HVs 17.9% 29.1% 37.6% 42.7%

Reduce Green House Gas Emissions

We are working to lower our FY2020 Scope 1 and Scope 2 emissions by 35% by FY2025.

- Switching to renewable energy (Okayama Factory)

- Reducing gasoline/petroleum consumption through the use of low-pollution vehicles (Eco cars).

- Reducing electricity consumption by switching to LED lights.

2020FY 2021FY 2022FY 2023FY Scope 1, 2 Emissions Vol. (kg-CO2) 6,526,468 6,617,641 6,569,380 4,864,145

-

Reduce and Recycle Plastic Waste

We are working to reduce plastic waste disposal and promote recycling in accordance with The Plastic Resource Circulation Act (Japan).

(1) Amount of disposed plastic waste.

(2) Achievement status of goals related to plastic waste recycling.Center Item 2021FY 2022FY 2023FY “Osaka Head Office

Research Building

Osaka Sales Office”Amount of plastic used in industry products

Amount of waste and disposed items425.5t 288.9t 163.3t Amount of plastic used in industry products

Ratio of waste and disposed items0.0% 4.2% 50.00% Okayama Factory Amount of plastic used in industry products

Amount of waste and disposed items814.9t 864.4t 860.9t Amount of plastic used in industry products

Ratio of waste and disposed items100.0% 100.0% 100.0% *Emissions from the Osaka Head Office, Research Building, and Osaka Sales Office were converted from volume to weight until August 2022, then partially to net weight from August 2022, and wholly to net weight in March 2023.

- In March 2023, our Osaka Head Office, Research Building, and Osaka Sales Office launched an initiative aimed at recycling plastic waste into Refuse Paper & Plastic Fuel (RPF) and will continue plastic recycling efforts toward this goal throughout FY2024.

- Our Okayama Factory is aiming to maintain a recycling rate of 100%.

(3) Progress of the goal for reducing plastic waste emissions.

- We aim to reduce the amount of plastic packaging materials used in products delivered to us from our suppliers by 50% compared to FY2021 until FY2023.

2021FY(Standards) 2022FY(Achievements) 2023FY(Achievements) 12,431 11,088 4,825 ** Annual air packing usage(m)

-

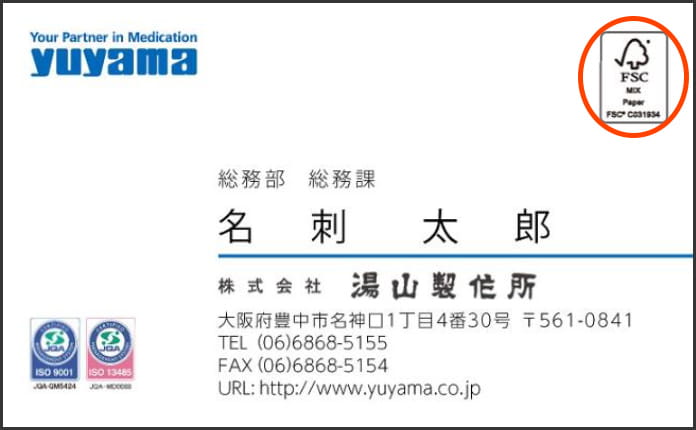

Use FSC-certified Paper

- Forest Stewardship Council certification is a system that certifies that timber and timber derived products are produced using trees from recognized and properly managed forests.

- From October 2020, we began using FSC-certified paper for all catalogue renewals and reprints.

- From May 2022, we began using FSC-certified paper for all business card renewals (new orders) and reprints.

-

Enforce Compliance

Our compliance enforcement operations serve to promote information security, protect trade secrets, prevent fraud or corruption, and eradicate antisocial forces or organized crime groups.

- Distribute compliance handbooks to all employees and conduct regular review meetings (reading sessions).

- Conduct internal audits through our Internal Control Division.

- Inclusion of a clause for “anti-social forces” in contracts.

May 2020 to

April 2021May 2021 to

April 2022May 2022 to

March 2023April 2023 to

March 2024Number of Internal Audits 10 37 56 59

-

Company-wide Environmental Data

2020FY 2021FY 2022FY 2023FY Electricity Consumption (kWh) 8,787,345 9,273,982 9,344,173 7,913,238 Water Consumption (m3) 11,178 11,303 14,151 13,538 “Amount of Copy Paper Purchased

*A4 equivalent “7,690,000 6,850,000 6,935,000 6,475,000 Gasoline Refueling (liters) 1,023,907 1,014,084 1,011,629 1,043,752 Diesel Fuel Consumption (liters) 105,211 101,118 99,290 96,521